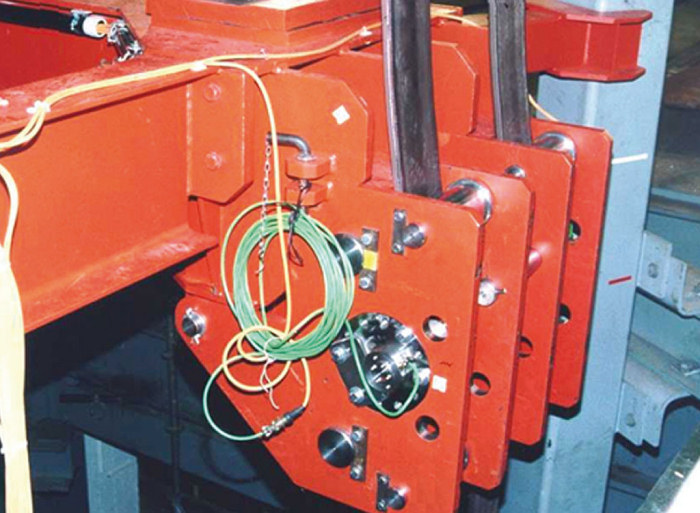

The principle of the Safety Arrestor is based on the dissipation of energy by plastic deformation of a ductile strip of material (such as mild steel) by sets of rollers over a large area. Hence it’s acronym name SELDA (Strain Energy Linear Ductile Arrestor). The kinetic energy is thus converted into strain energy which is safely released as low-grade heat. The Safety Arrestor consists of two or more strips suspended from the shaft steelwork which pass through roller boxes mounted on an arrestor frame.

In case of an overwinding situation, the conveyance hits the arrestor frame and the roller boxes are forced to run along the strips, thus stopping the conveyance in a controlled manner. The unit should be installed at both ends of the hoisting system and in each compartment to provide complete protection.

The Safety Arrestor replaces other means, such as tapered wooden guides, by which the hoisting conveyances are stopped without control. Such systems often cause major damage to the conveyances and steel work. The unit has the following advantages :

- Designed to suit any shaft

- Smooth and safe arresting of cages, skips, and counterweights

- Constant retardation

- Safe against overloading

- Conversion into strain energy

- Simple installation in any hoisting system

For further information please contact our Communications Manager.